VCT Floor Stripping Machines

VCT Dry-Stripping

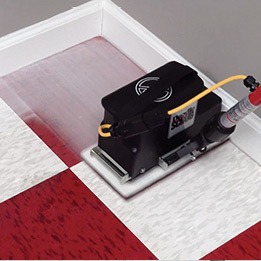

VCT, or Vinyl Composite Tile, floors are designed to have a protective coating of floor finish applied to them that takes the wear and tear from foot traffic while being easy to refresh. While most VCT floors are protected by four to six thin coats of floor finish, the damage caused by foot traffic is found in the top one or two coats. Dry stripping abrades the damaged coats of finish away, leaving undamaged floor finish intact on the floor. After abrasion, the remaining finish can be removed and new finish can be put down. This saves significant time, labor, and chemical costs over standard chemical stripping procedures.

1. Sweep the floor to remove dry soils.

2. Prepare the Pivot for dry-stripping.

1. Attach dust skirt to velcro around the base of the Pivot .

2. Install vacuum.

3. Plug vacuum into the block between the power cord and the motor.

4. Turn the power switch on the vacuum on so it powers on with the motor.

3. Apply a backer pad to protect the grip face of the Pivot or Doodle Scrub.- The White Driver Pad is recommended because the thin profile transfers more orbital action to the floor.- For uneven floors, one or two Blue or Red pads can be used to address low spots.

4. Apply SQP Pad to the backer pad

5. Cover the floor in long passes with a small overlap

6. SQP pads will cover approximately 300-400 square feet before they need to be flipped or exchanged

7. Vacuum, scrub, or mop the floor to remove the larger particles of pulverized finish on the floor

8. Once the floor is dry and no residue is found when wiping fingers across it, the floor is ready for new layers of finish

Tools Needed:

1/4″ White Driver

EBG-20/C PIVOT

SS P1420DRIVER

EBG-28 PIVOT

SS P1428DRIVER

Blue Driver

EBG-20/C PIVOT

SS P1420BLU

EBG-28 PIVOT

SS P1428BLU

SQP Pad

EBG-20/C PIVOT

SS P1420SQP

EBG-28 PIVOT

SS P1428SQP

Dust Skirt

EBG-20/C PIVOT

SS 142005

EBG-28 PIVOT

SS 142805

VCT Chemical Stripping

Chemical stripping is performed when all of the finish on a floor must be completely removed. In this process, a chemical is used to break the bonds between the polymers in the finish for removal. Performing chemical stripping with the Square Scrub Pivot is much safer than a low-speed machine since the small orbital pattern barely moves the machine when compared to the rapid movement right or left of the low-speed.

1. Follow finish manufacturers’ direction for application of floor stripper.

2. Apply a Blue Driver Pad for uneven floors. If the floor is extremely uneven apply two Blue Driver Pads.

3. Apply SHO Pad with a white Driver Pad.

4. Work into the area where the stripper has been applied and take long, overlapping passes.

5. Use the square corners of the Pivot to scrub in corners.

6. Use the Doodle Scrub with the same driver and SHO pad set-up to scrub along edges and into other small spaces.

7. Follow standard stripping procedures to keep the slurry from drying, recover the slurry, and ensure the floor is ready for floor finish to be applied..

8. Once the floor is dry and no residue is found when wiping fingers across it, the floor is ready for new layers of finish. Use the Square Scrub Bucket-on-a-Stick for fast application of floor finish and easy clean-up!

Tools Needed:

1/4″ White Driver

EBG-20/C PIVOT

SS P1420DRIVER

EBG-28 PIVOT

SS P1428DRIVER

Blue Driver

EBG-20/C PIVOT

SS P1420BLU

EBG-28 PIVOT

SS P1428BLU

SHO Pad

EBG-20/C PIVOT

SS P1420SHO

EBG-28 PIVOT

SS P1428SHO